PCBA Test Fixtures

Are you about to launch the manufacturing of your product but don’t know how to test your electronics during production?

At Microelectronicos we offer you our automated test fixture solutions for PCBA’s that require to be tested as a sub-assembly units before going into the final product. Our team of engineers have years of experience designing test fixtures for pcbas (printed circuit board assembly) for products that have gone into the market; automated test fixtures are mostly used in highly regulated industries like medical and aerospace to name a few.

This is ancho text

How to start?

Bring us your test requirements and board documentation (schematics, Gerber files, 3D Files, firmware if necessary) and we will provide you with a quote of our test fixture development services.

Anchor text

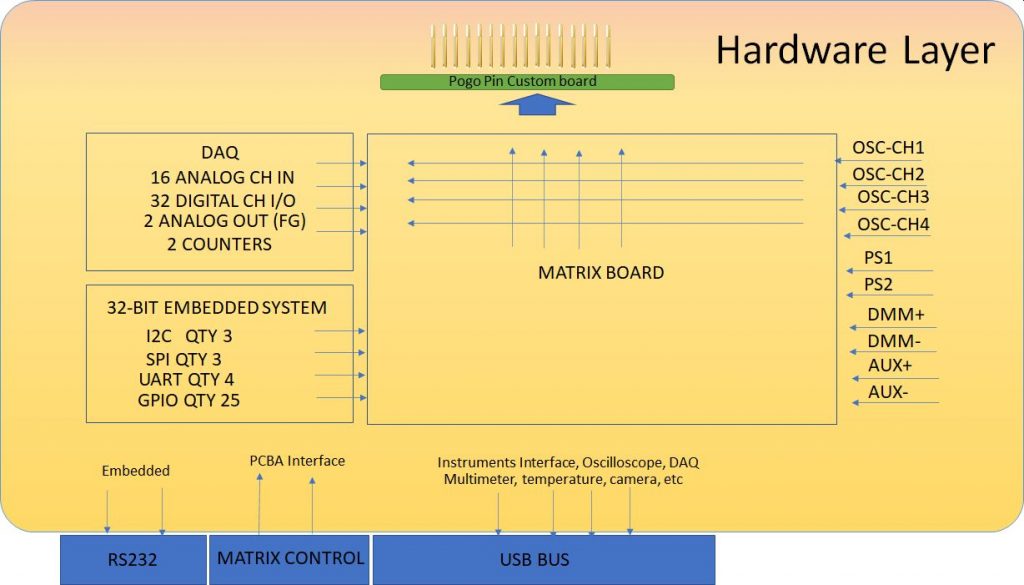

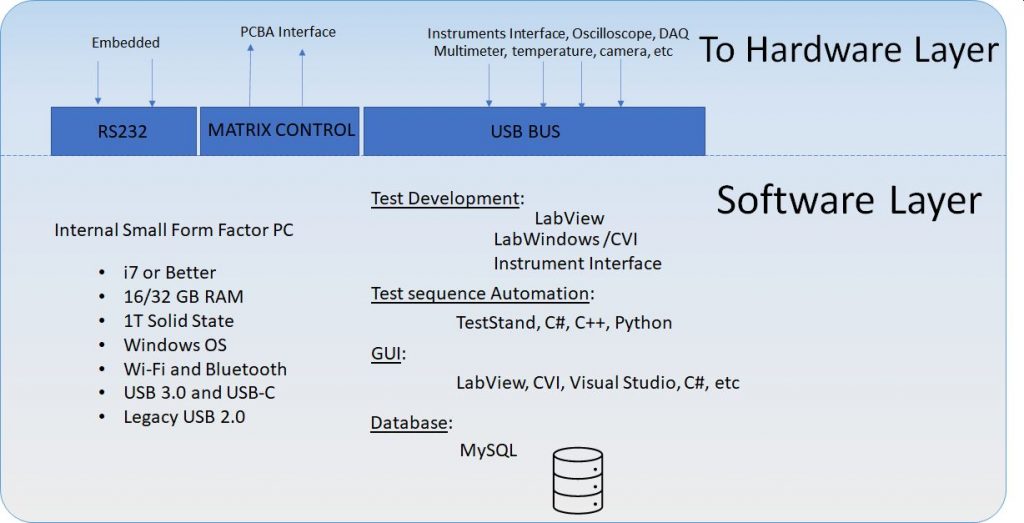

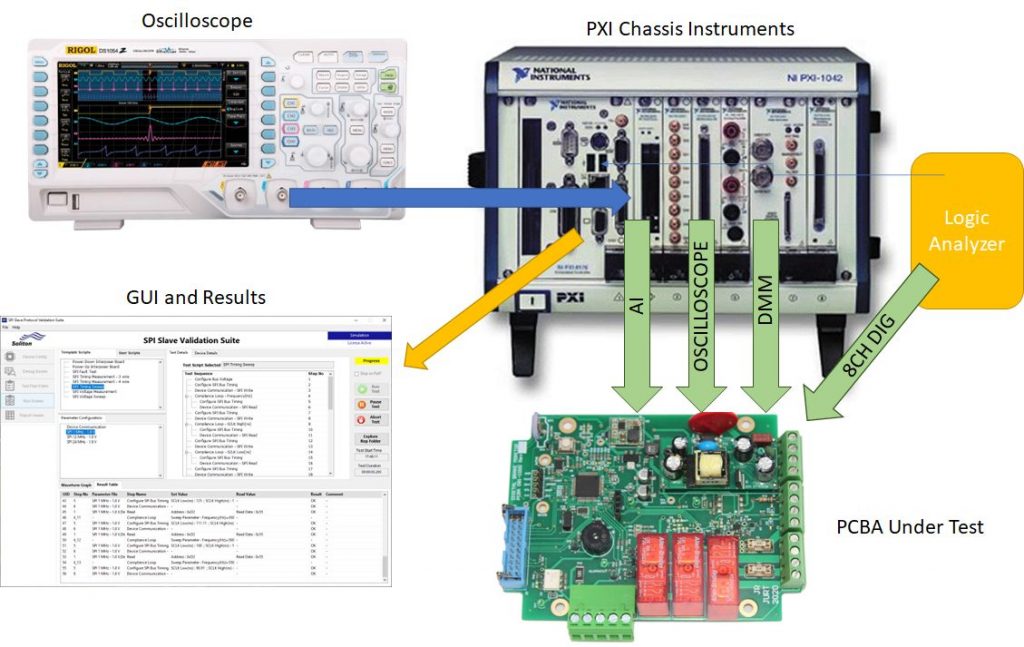

Overall architecture

Test Equipment

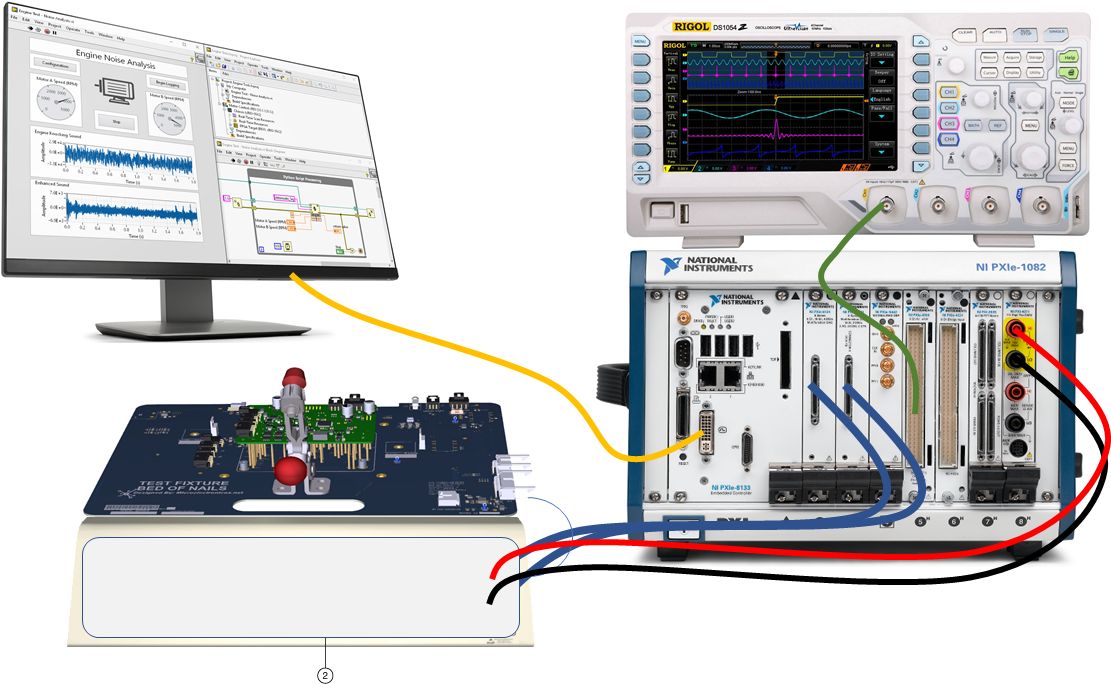

Our typical solution for PCBA test fixture is shown in the Figure 3. We used a mixed-approach of off-the-shelf bench instruments (like oscilloscopes, function generators, spectrum analyzers, programable power supplies, etc.) which in general tend to be low-cost in addition to the typical PXI chassis rack configured with DAQ boards and other dedicated instrumentation capabilities (relay switching, DMM, high-resolution ADC’s and DAC’s, etc.) . This architecture allow us to get the most of two worlds (off-the-shelf instruments vs PXI devices) in different electronics test scenarios with the purpose of achieving configuration flexibility, high performance and low cost.

This is anchor text

Our Solution

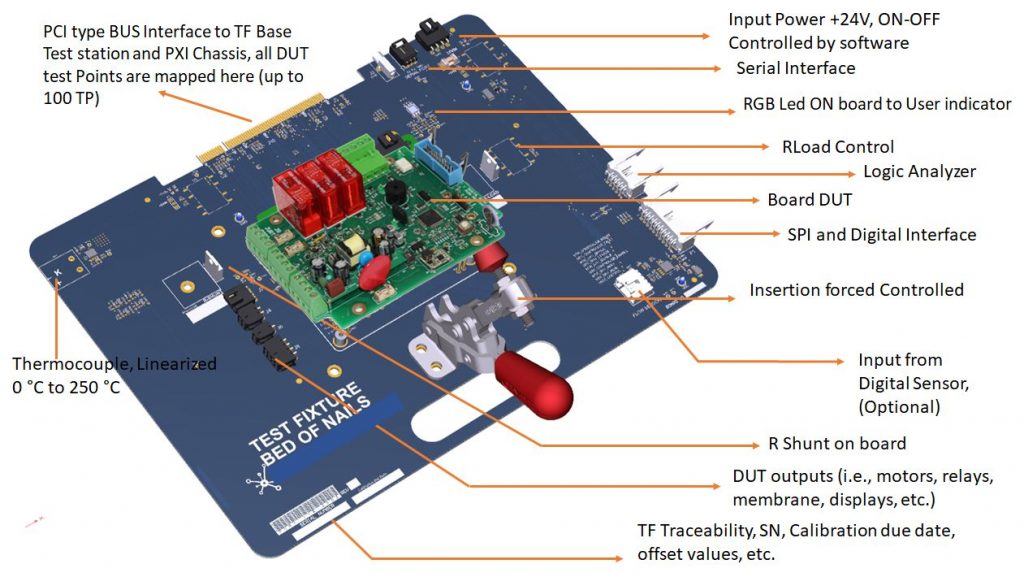

Pogo Pin Mezzanine board (to DUT)

We will develop custom interface boards with spring-type pins (a.k.a “pogo-pins”) that will get contact with the board under test and access the test points. Our interface board will provide power to the DUT and also perform the necessary signal conditioning so the test points can be correctly routed to the appropriate test instrument.

An example of such board is shown in figure 5 (conditioning board on blue and DUT board on green):

Anchor text line here Automated Test Fixture with National Instruments LabView LabWindows

One of the key elements of a successful test fixture is the interface with the PCBA DUT (Device Under Test). Our custom Pogo-pin Mezzanine board will interface with your PCBA and perform all the signal conditioning necessary to interface your device with the appropriate test instruments. We also have included key elements in the design like:

- EEPROM Memory to store Test fixture calibration information, serial number, offset values, typical values, calibration date, regular test fixture users, calibration temperature, etc. All these elements are key to maintain traceability of your test equipment and comply with regulatory guidelines (i.e. IQ, OQ, PQ for test fixtures for Medical designs).

- On board temperature sensor that will allow you to monitor high power, temperature sensitive components like: heat sinks, voltage regulators, shunt resistors, high power MOSFETS, etc.

- Programmable ON/OFF switch, so your DUT can be powered under software control.

- RGB Led to indicate test progress and status: Warning, failed, pass, test halted, test skipped, etc.

- Interface to Logic Analyzer: will allow to analyze communication protocols like: I2C, SPI, USB, CAN and Serial, on-the-fly.

- Clamp to control insertion force of your PCBA into the pogo board.

Click here to learn more about our complete test rack solution for PCBA test fixtures. Please contact us to discuss your Automated PCBA Test needs!

engineering@microelectronicos.com ________Phone: (949) 2261622